|

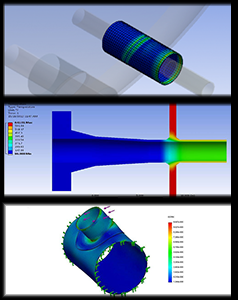

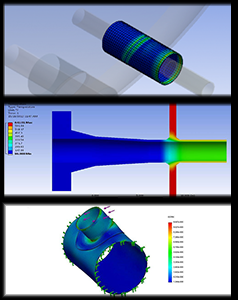

Finite Element Analysis (FEA)

|

|

- Large bore pipe loading (B31.3)

- Pressure Vessel nozzle loading (ASME VIII Div 2)

- Compressor shaft fretting and fatigue

- Reactor wall thermal quenching

- LNG vacuum jacketing vessel and pump nozzle loading

- Salt bath heather nozzle cracking study

|

|

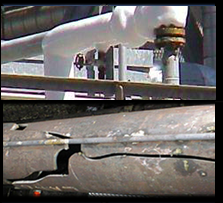

Fitness for Service (FFS)

|

|

- On-Site Inspection

- Equipment Life Expectancy Assessment

- Reactor

- Electric Shuffler

- Excavator

- Steam Injection Point

- Rotary Breaker

|

|

Material Engineering

|

|

- Material Corrosion Study

- Material Upgrade

- Low Temperature Brittle Fracture Prevention

|

|

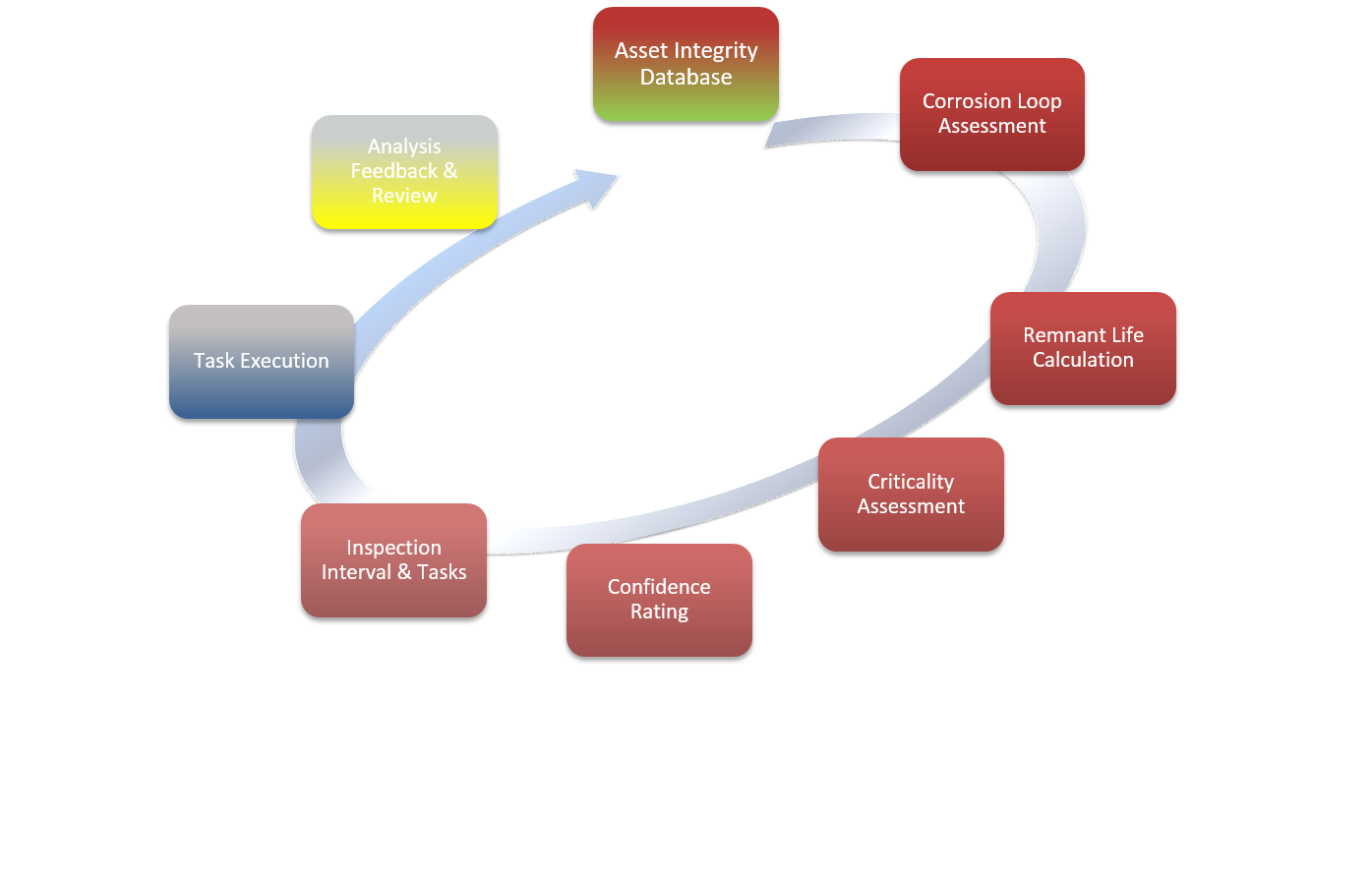

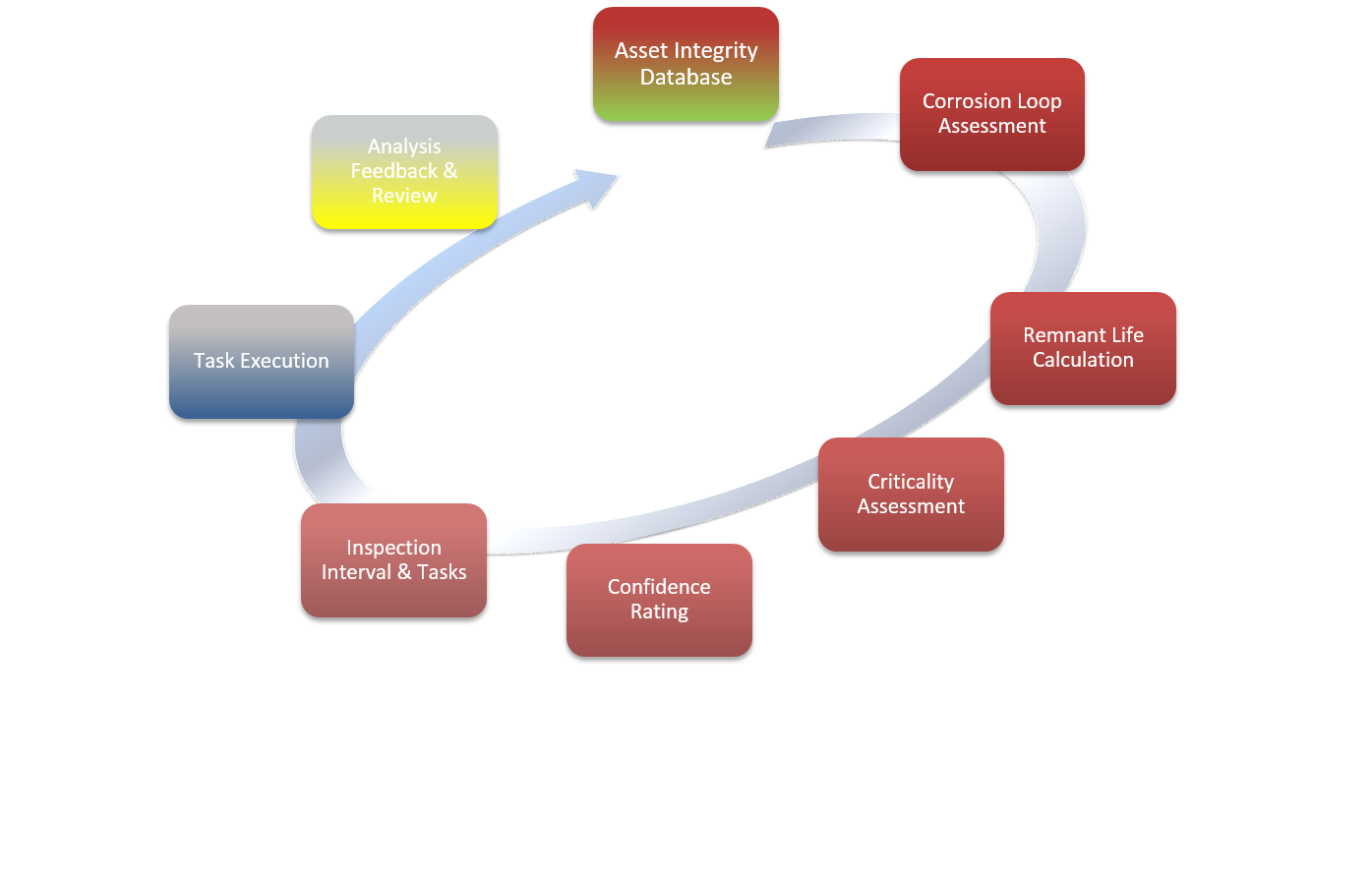

Risk Based Inspection

|

|

- Acidic Sour Water Corrosion

- Underdeposit Corrosion

- Caustic Corrosion

- Lean Amine Corrosion

- Chloride pitting

- Hydrochloric Acid Corrosion

- Organic Acid Corrosion

- Wet CO2 Corrosion (Carbonic acid corrosion)

- Sulphidation (Sulphidic Corrosion)

- Erosion corrosion

- Brittle Fracture

- Mechanical Fatigue

- Thermal Fatigue

- Cracking (e.g Carbonate Stress corrosion cracking, Sulphide Stress

Cracking, etc)

- High Temperature Degradation (Creep, Temper Embrittlement,

High Temp. Hydrogen Attack (HTHA), etc)

|

|

| Copyright © Zachry Canada Ltd. |

.jpg)