Success Stories

A few of our featured projects are listed below:

- FEA of Heavy-Duty Trucks Can Save Up To $82 Million/Year

- Cold Brittle Fracture Analysis Prevents Future Failure

- Critical Service Piping Deflection Mitigated with New Supports

- Start-up Optimization of Vessels can Result in Production Profits of Over $10 Million

- Fitness For Fitness Evaluation Saves on Costly Replacement

FEA of Heavy-Duty Trucks Can Save Up To $82 Million/Year

Problem

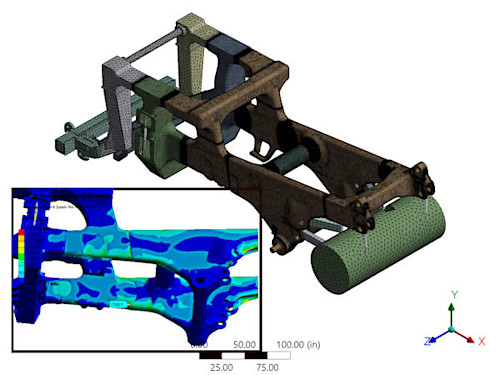

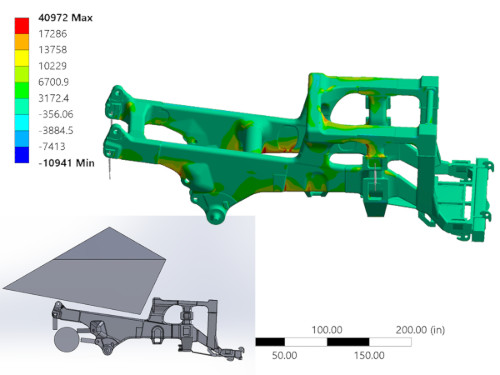

Our client wanted to extend the service life of the heavy-duty mining truck frames. Costly expenses, estimated at $82 million/year, were accruing from lost production without considering repair material, labour, and HSE impact.

Action

Zachry’s team of engineers worked together to develop a solution involving:

- Combined approach of fatigue assessment (ASME Section VIII-2) and brittle fracture assessment (API 579-1 Part 9) methodologies.

- 3D laser scan of the truck frame and FEA using ANSYS of a 285 ton truck with a 400 ton bucket load. Various operating scenarios such as loading, unloading and turning while fully loaded were considered.

- Calculations of stress ranges and allowable cycles to determine the conditions that caused the most fatigue damage and the limiting crack size before brittle fracture failure.

|

|

Result

- Extended service life by recommending new ore payloads. New guidelines for maximum acceptable crack depth for longer service time between repairs were provided.

- Recommendations to reduce severity and occurrence of future cracks with NDE inspection and post-weld heat treatment.

- Savings of up to $82 million for our client.

Cold Brittle Fracture Analysis Prevents Future Failure

Problem

Our client was throttling fuel gas from high to low pressure for injection to steam lines in five SAGD well pads. The Joule-Thomson effect across control valves can create the conditions for cold brittle fracture failure. It was discovered that the fuel gas temperature on the in-service fuel gas lines were dropping below minimum design temperature. Cold brittle fracture failure could cause production downtime and lost profits.

Action

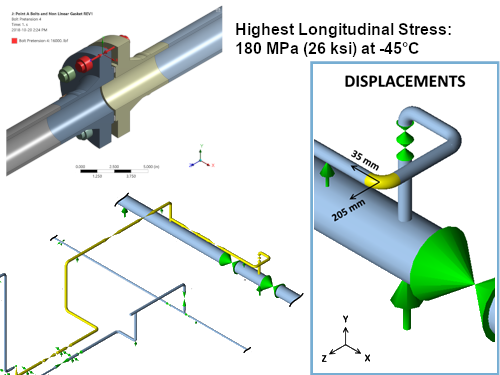

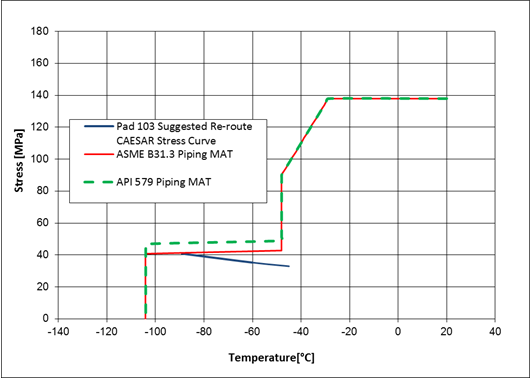

Zachry proposed a systematic Fitness For Service solution to determine whether the existing piping design was safe for continued use. Our engineers used best practices from API 579/ASME FFS-1 to conduct:

- Level 2 Assessments for piping components in the affected systems with four out of five pads deemed to be not at-risk for brittle fracture.

- Level 3 Assessment involving Finite Element Analysis for the flanges that did not pass the Level 2 Assessment. The Level 3 flange assesssment deemed the flanges not at-risk for brittle fracture failure. On the fifth pad, longitudinal stresses exceeded 100 Mpa (due to large thermal displacements) which caused the piping system to fail the Level 2 Assessment and was deemed at-risk for brittle fracture failure. To improve the piping flexibility and pass ASME B31.3 and API 579/ASME FFS-1 criteria, a minor piping re-route was proposed.

|

|

Result

- Brittle fracture prevention using simple piping modification on one out of five well pads.

- Budget and time-savings for our customer by using a tiered assessment approach.

- Continued safe operation for our client—eliminate potential downtime by deeming the affected systems to be not at-risk for brittle fracture.

Critical Service Piping Deflection Mitigated with New Supports

Problem

Our client discovered a crack and dent on a critical service piping header that experiences rapid & cyclic changes in temperature as part of normal operation. In the past, sections of the header had seen repairs, replacements and overlay welds. Constant effort springs and snubbers had been installed in an effort to mitigate deflection issues but with no success. Zachry was contacted to conduct a review of the header, including a Fitness For Service evaluation.

Action

Zachry’s team of engineers worked together to develop a solution involving:

- A CAESAR II model using design information and deflection laser readings was created to perform piping flexibility and static analysis Process loading conditions for three cases were used:

A. Current field-adjusted loading conditions

B. Original spring loading conditions

C. New conditions with support recommendation - Our engineers suggested three recommendations to reduce the piping stress—1. Adjust the spring loading settings, 2. Remove snubbers, and 3. Add new supports to reduce pipe sag.

- A Finite Element Analysis of the dented portion was performed in ANSYS to verify integrity under design and operating conditions with new Weld Metal Overlay.

Result

- A CWP package was created for the client detailing the procedures to implement the new supports and spring replacements.

- A Weld Metal Overlay satisfied ASME Code compliance checks and a new NDE inspection monitoring program to future crack propagation was initiated.

- Ultimately, Zachry helped to correct support problems on a critical service piping header, allowing for continued safer operation.

Start-up Optimization of Vessels can Increase Production Profits Upwards of $10 Million

Problem

Our client operates heavy-walled vessels in their upgrading facility for a hydroconversion process. These vessels require numerous days to heat up after maintenance turnarounds leading to tremendous economic incentive to increase the speed of the heat up phase. However, doing so requires consideration of equipment safety and application of brittle fracture principles. Zachry worked closely with the client’s Mechanical, Materials, Process, and Operations teams to optimize the heat up procedure.

Action

-

- Our engineers took action to:

- Understand the existing heat up procedure, pressure limits, temperature limits, heat-up rates, and operational levers

- Understand the vessel’s material fracture toughness behavior

- Perform heat transfer and structural Finite Element Analysis in an iterative process to assess & optimize the planned start-up procedure to meet safe limits

Result

- Eliminated numerous obstacles associated with pressurization of process equipment

- Widened start-up operating envelopes for the Operations team

- Reduced the time required to start-up by over a day, thereby increasing production and profits by upwards of $10 million

Fitness For Fitness Evaluation Saves on Costly Replacement

Problem

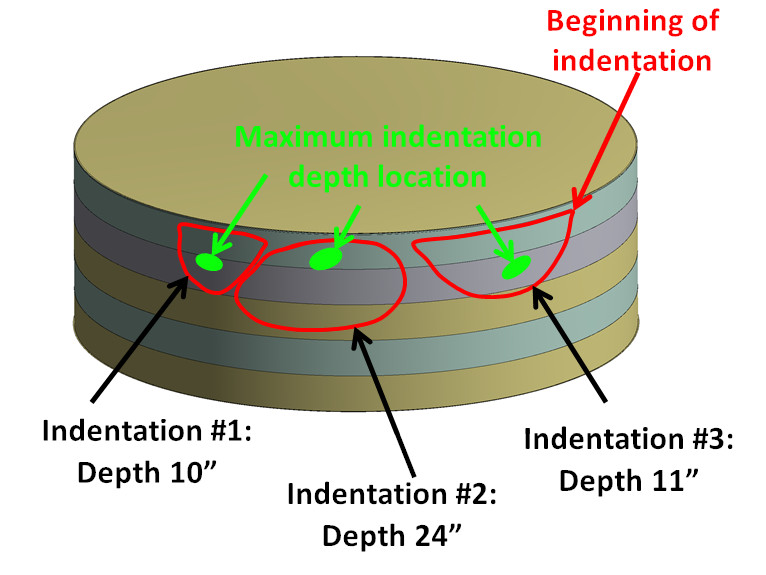

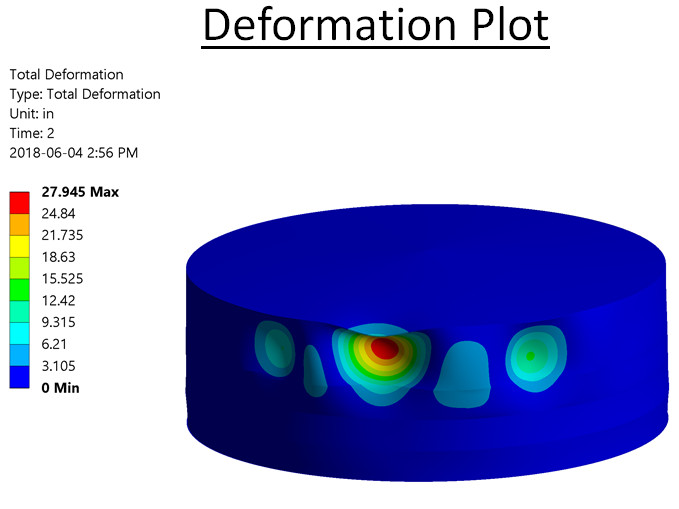

A kerosene storage tank was damaged in a vacuum event that caused deformations to occur around the entire circumference of the tank. The cause was determined to be a relief device that did not function to relieve negative internal pressure inside the tank.

Observations of the tank revealed 7 dents had formed along the top 3 courses of the tank. Zachry was contacted to perform a Fitness For Service evaluation to determine the serviceability of the tank.

Action

- A 3D model of the damaged tank was developed using SolidWorks.

- Four failure cases were analyzed using Finite Element Analysis in ANSYS to determine the serviceability of the kerosene storage tank:

- Plastic Collapse

- Local Failure

- Buckling

- Ratcheting

Result

- The analysis concluded that the tank was serviceable under current operating conditions with new restrictions on maximum liquid level.

- Ultimately, our client was able to save millions on capital and downtime related to the purchase of a new storage tank.

{